204.355.8565

204.355.8565 reiner@RWFmalting.com

reiner@RWFmalting.com

kilning

the final step to our process

the final step to our process

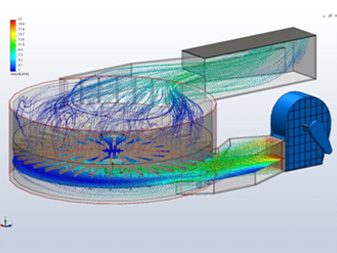

RWF offers kilns which are cost effective systems for drying malt; they may be rectangular or circular in design and are equipped with:

- Efficient variable high speed fans

- Stainless Steel or Glass Tube Heat Exchangers

- Anox burner system for indirect heating.

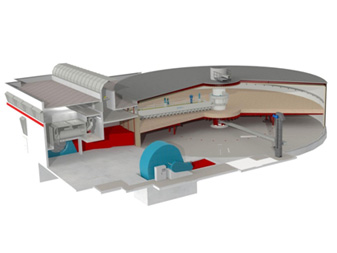

Loading and discharge is totally automated. The circular vessels are built in stainless steel and are fully insulated. They can be designed with either a fixed or rotating floor combined with a fixed or rotating loading discharge machine. Kilns can be designed as a single vessel, a double vessel or even a combined germinating kilning vessel.

Loading and discharge is totally automated. The circular vessels are built in stainless steel and are fully insulated. They can be designed with either a fixed or rotating floor combined with a fixed or rotating loading discharge machine. Kilns can be designed as a single vessel, a double vessel or even a combined germinating kilning vessel.

In the single vessel kiln the air is preheated by the heat exchanger, then heated to the required temperature by the Anox burner, blown through the malt by the fans and discharged through the heat exchanger to atmosphere.

The combination of the heat exchanger and the Anox burners obtains high efficiency and achieves a very low energy consumption using the single vessel kiln or double vessel kiln system.

The double kilning vessel system can be built side by side or one on top of the other. The kilning air can either move from the curing kiln to the withering kiln or the malt is transferred from the withering kiln to the curing kiln. The combined germination and kilning vessel has the benefit of no green malt movement and is a very hygienic system.